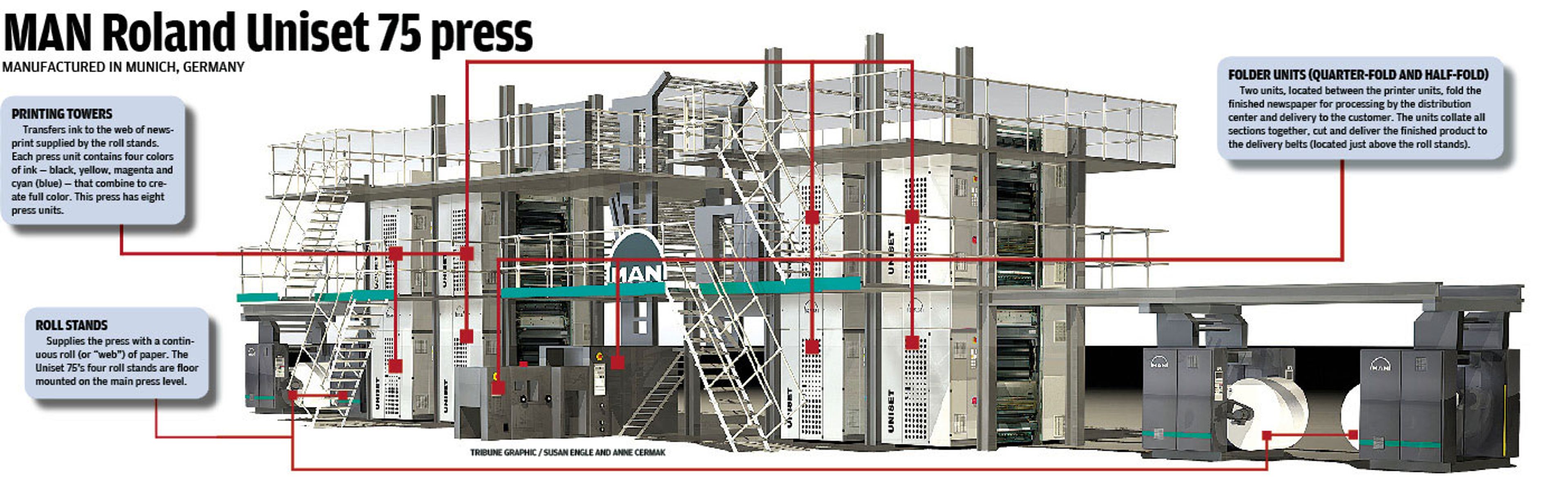

The arrival of the MAN Roland Uniset 75 offset newspaper press at TPC Holdings signals the computerization of a process that until now relied largely on the muscle of men.

Mechanical arms controlled by computers now thread rolls of paper into the press for the editions of the Lewiston Tribune and the Moscow-Pullman Daily News. The job previously was done manually.

Computer modules regulate the amount of ink on each page and the color in every picture. Those processes were previously adjusted by the press crew at individual stations.

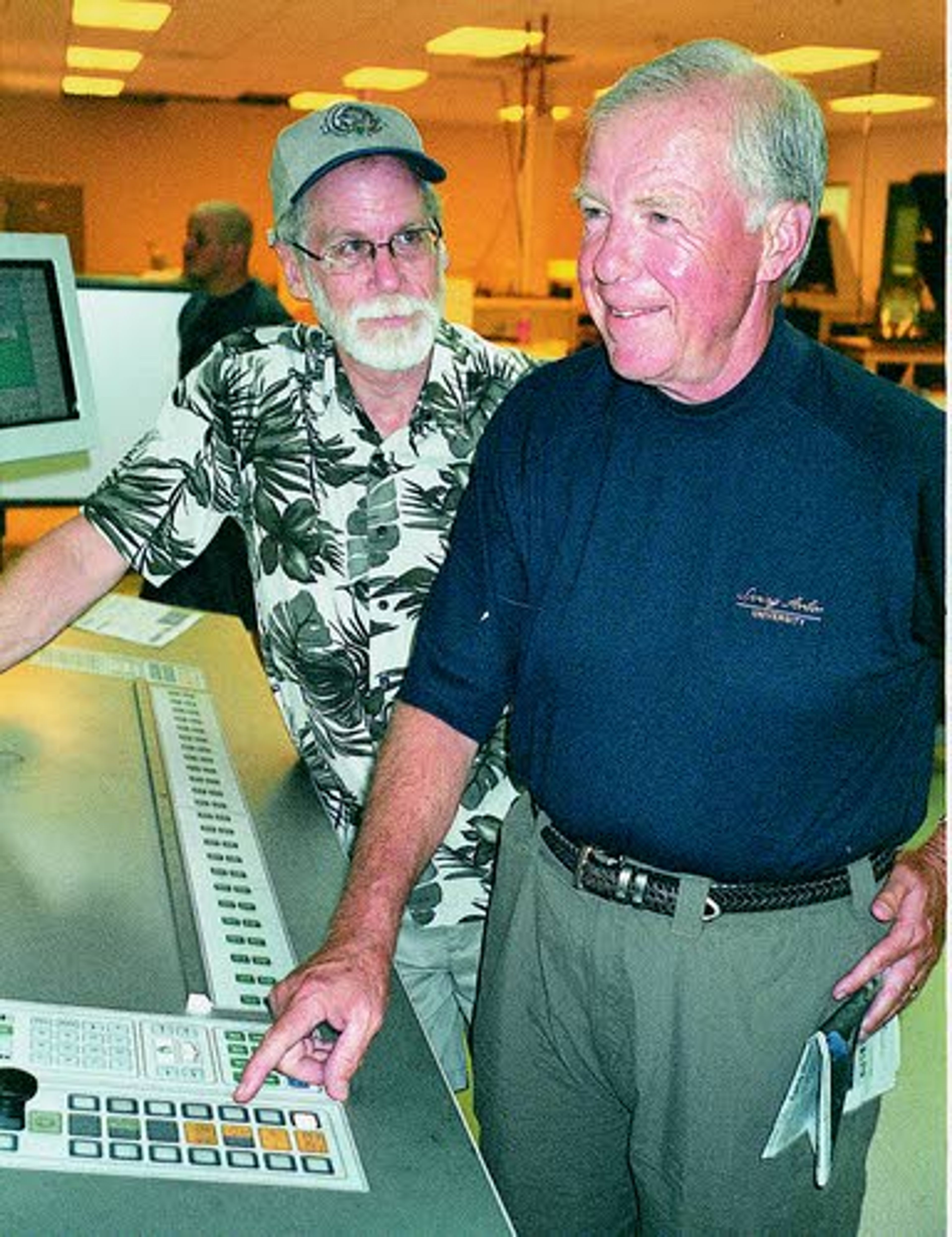

The changes are among a handful of giant steps forward the newspapers have taken in their history, which spans more than a century, says A.L. (Butch) Alford Jr., president of TPC Holdings and editor and publisher of the Lewiston Tribune.

TPC Holdings Inc., the parent company for the two newspapers, made a significant investment in the technology. The project cost $12 million. That includes the 32,000-square-foot building constructed adjacent to the main Tribune office at 505 Capital St. in Lewiston to house the press and distribution center. "The end result is a product that is far superior," Alford says.

The decision to purchase a new press comes at a time when a number of newspapers throughout the nation are cutting employees as their circulation declines.

The outlook for this region's daily newspapers is brighter and TPC Holdings wants to stand ready to serve its customers with the best possible news product regardless of the format they prefer, Alford says.

The Tribune and Daily News have more subscribers per capita than other U.S. newspapers in similar-sized markets, Alford says. The Tribune has a circulation of 25,000 and the Daily News has 8,000 subscribers.

"The studies show there's a future ahead for print, but many, mostly younger readers, also like electronic delivery on computers or handheld devices," Alford says. "The key for us is to give our customers three choices in print, electronic or both."

Alford puts himself in that latter category. He reads his newspaper in the traditional format when he's in town and online when he's not.

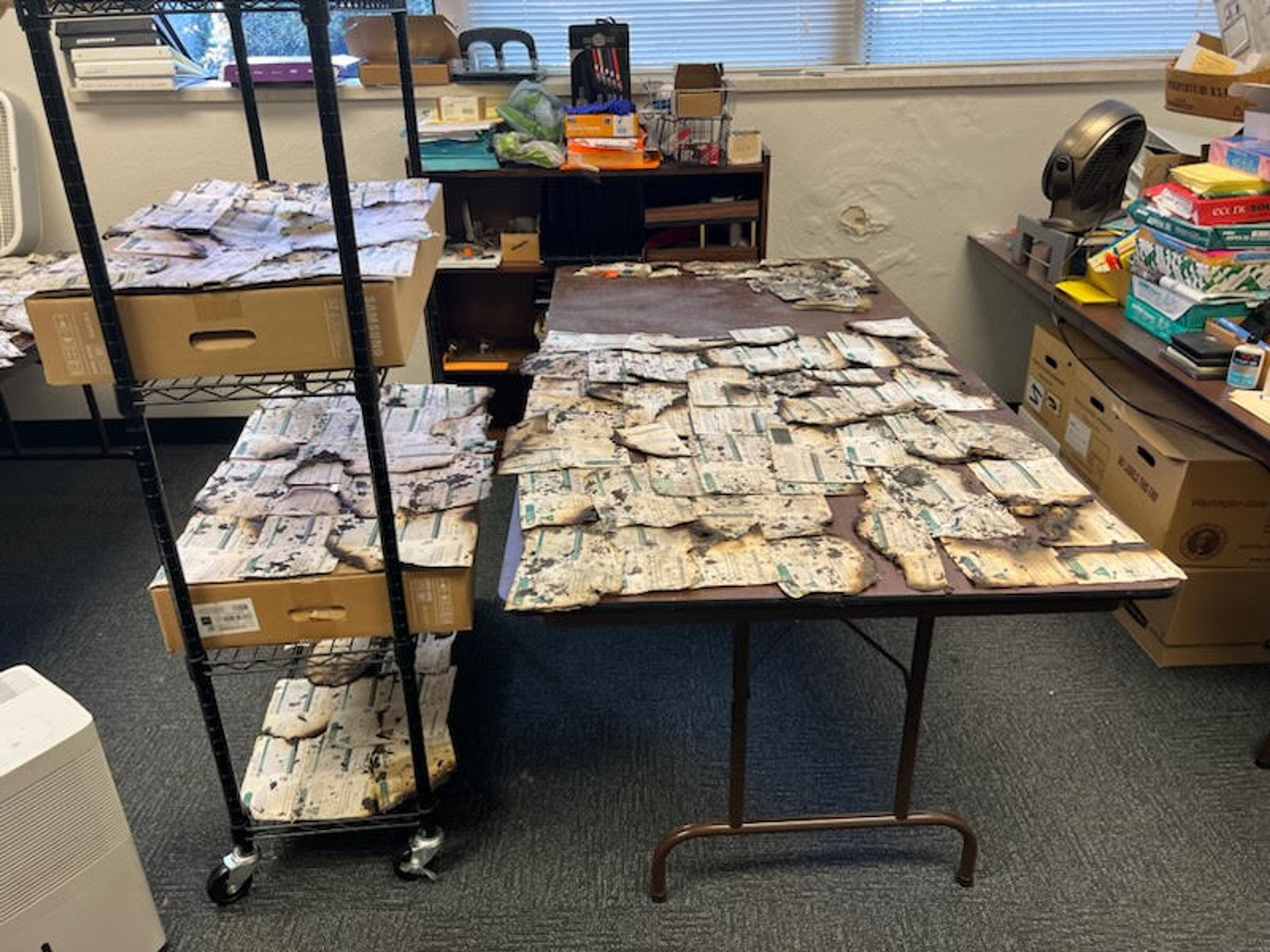

Another factor in the decision was the demise of the 32-year-old Harris offset press in Moscow that served the Daily News. In 2006, printing of the Daily News shifted to Lewiston after it had to be run at the Tribune less than a half a dozen times on an emergency basis.

"We could have continued that for more than two decades," Alford says. "Instead we decided to invest in major improvements in the press to the advantage of both the Daily News and the Tribune."

The Uniset 75 is expected to generate more business for the newspapers and their advertisers, Alford says. The higher speed of the new press will allow TPC Holdings to seek new commercial printing accounts.

TPC Holdings already has a robust business in those areas. It prints advertising supplements, a number of weeklies, such as the Idaho County Free Press, and specialty publications such as Happy Trails, which focuses on horse-related news. But the old press couldn't accommodate any more business because of a lack of capacity.

At the same time, the new press should boost advertising revenue, Alford says. Readers are 50 percent more likely to act on an advertisement that runs in color than one that appears in black and white.

The Uniset 75 can print color on all pages of the newspaper, not just eight pages like the one it replaced. The newspapers are lowering their rates for color advertisements to help their customers take advantage of the new press, Alford says.

The Uniset 75 will help the bottom line in other ways as well. It uses less ink, electricity and paper than the press it replaces. The savings is expected to total between $200,000 and $300,000 annually, Alford says.

None of the savings will come from reducing staff, Alford says. It's possible as employees retire or move to other jobs that they may not be replaced, but it's also possible the size of the press crew will remain the same as commercial business grows, Alford says. "We frankly don't know."

Extensive as the project was, TPC Holdings would like to follow up with even more improvements, Alford says. A third line of used machines for inserting advertising supplements was added in the distribution center to help keep pace with the speed of the new press.

All of that inserting equipment, some of which dates back to the 1960s, may be replaced in five to six years, Alford says.

"Obviously TPC Holdings is optimistic about the Idaho-Washington region we serve," Alford says. "We view the new production center and press as first being a wise investment in ourselves and second as being an astute investment in the many communities we serve."

---

Williams may be contacted at ewilliam@lmtribune.com or (208) 848-2261.